The lesson is simple: When something is working exceptionally well, stick with it!

Facing Growing Pains and Inefficiencies

Texas-based Ogburn’s Truck Parts was founded in 1965 and, by 1996, had expanded to six locations; but all were operating independently — and inefficiently. Each had its own system and on-site server, with zero connectivity between systems. Communication between locations was via outdated point-to-point modems and many operations were labor-intensive, such as hand-written orders, which were distributed by FAX.

Recognizing the need to upgrade and consolidate operations and to establish visibility across the organization, Russ Smith and other company managers decided to evaluate providers of HD truck parts distribution management solutions. So, they attended an industry trade show in Atlanta that year for just that purpose.

The Need for a Tailored Solution

“First, we met with the largest provider at the time, who simply offered their standard system,” explained Smith, who is now the company’s Director of Purchasing and IT. “But we didn’t think it adequately addressed an array of needs specific to our company. Then, when we met with the AutoPower team, they asked many questions about all aspects of our business, and at the conclusion of our discussions, they committed to ensuring their distribution management system would meet our specific requirements. That commitment, along with their deep knowledge of the HD parts industry, made it clear we found our partner.”

According to Smith, in the months that followed, they made good on that commitment. Custom features and functions were integrated into AutoPower’s comprehensive distribution management system (DMS), and the company’s large volume of existing data was correlated, normalized, and ported over to the new system. This was followed by rigorous system testing and user training, then the system was successfully launched in 1997.

The Impact

With AutoPower, the company’s extensive parts inventory could be expressed in common part numbers across all locations and was visible and instantly accessible to all authorized personnel. Additionally, reporting for all operations, from sales management to warehouse management, was no longer fragmented and prone to errors, and all financial accounting functions were dramatically streamlined.

In close collaboration with Ogburn’s, AutoPower continued upgrade and, when necessary, adapt the system over the past two and a half decades, ensuring that the company always benefited from the most current technology. Ogburn’s even relocated its system to AutoPower’s secure hosting center for improved security management, automated backups, and improved infrastructure management. Their email server was relocated there, as well. In another recent upgrade, AutoPower helped the company replace its outmoded dot matrix barcode printers with industrial-class, high-capacity laser printers.

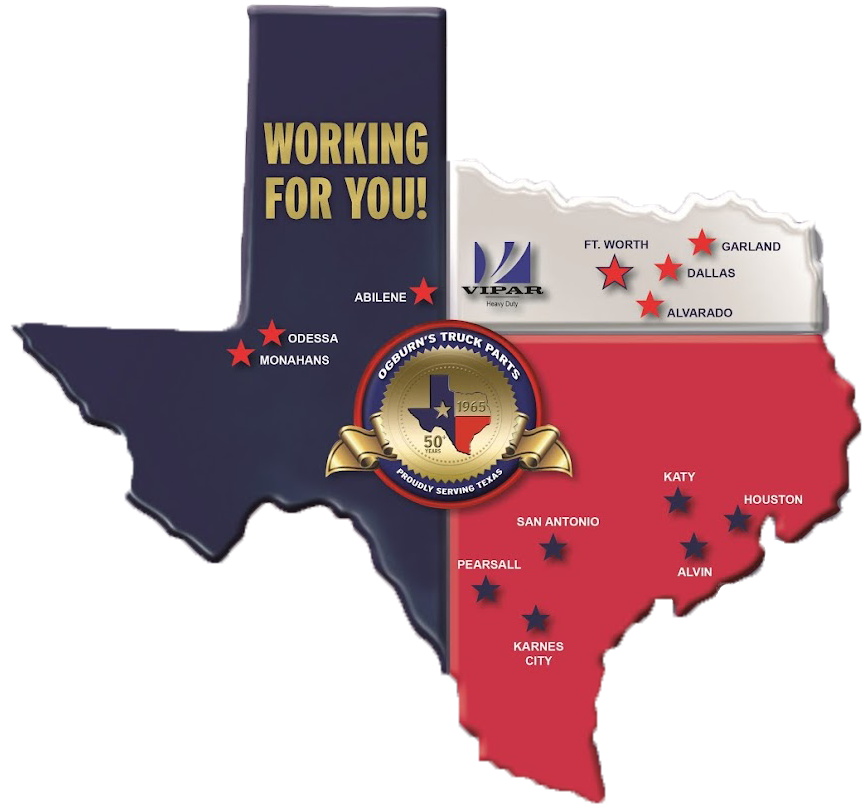

With the help of its AutoPower system, Ogburn’s is now the largest family-owned HD distributor in Texas, having grown to 120+ employees at 13 locations and offering 16 bumper-to-bumper HD parts categories.

The Next Big Thing

According to Russ Smith, the next move for Ogburn’s will be the move to AutoMaster, which delivers the AutoPower System under an evergreen method of continuous updates. It is designed to improve the system continually and automatically and will do so with little disruption to Ogburn’s business operations and budget. “This will allow us the benefits of a continuously improving management system in a way that’s affordable, includes great support, and requires minimal training,” He explained. “Most importantly, it will help drive our growth well into the future.”